How is the knitting going for everyone in the knit-along? I admit I haven’t touched my Briar Rose in awhile, but only because I have a (personally set) tighter deadline for another knit so I’m trying to bang out some work on that one before I go back to Briar Rose. I have about 6″ of the body done, and I’m working in the round.

How is the knitting going for everyone in the knit-along? I admit I haven’t touched my Briar Rose in awhile, but only because I have a (personally set) tighter deadline for another knit so I’m trying to bang out some work on that one before I go back to Briar Rose. I have about 6″ of the body done, and I’m working in the round.

Today, a few days early, I’m going to talk about sleeve caps. I bet going into this you had no idea that there was this much to cover in a little sleeve cap, did you? In fact, this sleeve cap post is actually longer than the resizing post for the entire rest of the sweater. Be forewarned! This is a good time to grab an alcoholic or non-alcoholic beverage of choice and get confortable.

A few basics about set-in sleeve caps in knitting

A sleeve cap is shaped to fit into an armhole. This might seem obvious when you read it, but I don’t think everyone actually thinks about this fact (who’s sitting around thinking about sleeve caps, anyway?).

But you have to figure out how to DO that. You want to knit a sleeve cap that will correctly fit into the armhole of your sweater. You don’t want it to pull too tightly across your shoulder, and you don’t want it to be too saggy and have extra fullness where you didn’t intend. Like Goldilocks, you want it to be just right.

The easy part is knitting the armhole of the sweater, and if you’ve resized Briar Rose or are knitting it as written, you will have this part covered.

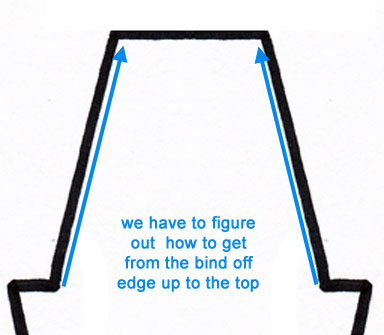

The more difficult part is shaping the sleeve cap. This:

does not translate into knitting magically. It takes some math to get there. You need to know how tall to knit your sleeve cap, when to work decreases along both edges, and how wide it should be at the very top of the cap when you bind off the rest of the stitches on your needle.

As a general rule, the perimeter of the sleeve cap needs to be the same as the perimeter of the armhole of your sweater (armscye). The sleeve cap can be up to about an inch or so larger, since you can ease that in, but you don’t want it smaller as that will cause the cap to pull across your shoulder. So let’s amend that to say that the perimeter of the sleeve cap should be the same or slightly larger than the sweater’s armscye.

We can break the sleeve cap down into three general areas that we will use to build the shape of the cap:

- the stitches you bind off at the beginning of the sleeve cap

- the sloped side (sloped by your decreases)

- the top of the sleeve cap (the stitches you bind off at the very end)

Before we begin

There are lots of ways to approach how to figure out sleeve caps. I’m sorry to say there is no one right way. I’ve spent a lot of time exhaustively reading resources and playing around with numbers so that I could provide as much information to you on this topic as possible, and let me tell you, not one resource says exactly the same thing. Changing styles, personal preference… this all comes into play. But the one constant is this: the sleeve cap has to fit into the armhole.

I’m going to show you two different ways to create a sleeve cap for our knitting pattern. (Again, they are not the only ways to do it, just the two ways I decided were best to present for the KAL.) One involves using the Pythagorean Theorem. It isn’t hard with a calculator, and you can even use a web site to calculate it for you. But I know the thought of more than basic arithmetic sends some people screaming. So I’m also going to show you another way to do it, which uses all the same numbers but instead of calculating an equation, you’ll be using pieces of paper to do it for you. You’ll create an outline in the actual size of your sleeve cap (think of it kind of like the outline of a sewing pattern piece for a sleeve). It takes longer to explain than it does to actually do. I’ll show it first so as not to scare you away with math formulas. Take a look at both methods and decide which one you’d like to try.

In both cases, I’m going to ask you to knit the body of your sweater first and block it, so this post is something you’re going to have to revisit. The reason is that you’re going to use your actual sweater to determine the perimeter of your armscye. You CAN calculate this using the Pythagorean Theorem as well, for those of you who want to be prepared ahead of time. But since I felt we’d have enough to tackle figuring out the math for the sleeve cap, I chose not to explain that method in this post. (But please let me know if you’d like to know how to do this, as I can post a thread on it in the Flickr group.)

One more thing… let me reiterate there’s no one right way to design a sleeve cap. I’m showing you what I find has worked for me, based on all of the research I’ve done. By no means does that mean this is the only way to do it. So I encourage you to explore! Just remember that fundamental rule: the perimeter of the sleeve cap needs to be the same as the perimeter of the armhole of your sweater (armscye), or slightly larger (but not smaller). Various ways to shape a cap aside, that’s the one thing you can’t be flexible on.

(Note: there are actually exceptions for fancier sleeve caps involving gathers and pleats much like a sleeve cap in a sewing pattern, but for a “normal” fitted set-in sleeve, this is the case. You’ll actually see this exception play out when I talk about pleated sleeve caps later on in this post.)

Ready? Let’s start.

Part 1: Preparation

There are several simple preparation steps that you need to complete to gather the numbers you’ll need to calculate the shape of your sleeve cap. We’ll be gathering 7 initial measurements.

I’m going to use labeled measurements like I did in my post on resizing, and for anyone who used my steps to resize Briar Rose I don’t want you to get your measurements mixed up, so I’ll start where I left off in the alphabet in that post. Thus we’ll begin with Measurement L. If you’re someone who is reading this post at some point in the future don’t worry—there aren’t Measurements A through K involved in shaping a sleeve cap. 😉

To make it a little easier when you go through to gather your numbers, I created a list of all of the measurements from this post that you can print out, providing my numbers as an example and space to write yours. That list is here. (**Note that I may change my measurements when I actually knit the sleeve, especially considering you will see I measured my armhole on a different sweater of mine, not Briar Rose. Please don’t count on my numbers being accurate! I’m just showing them to you as an example.)

Prep step 1: Measure a sweater to determine your armscye perimeter

Lay your blocked sweater on a flat surface. Take a piece of yarn or string and starting at the upper shoulder seam at the very edge of the garment, measure on top of the actual edge of the knitting (as opposed to inside the curve on the table, which might give you a slightly smaller number). Measure down around the armhole to the seam, or where the seam would be if you knit it in the round.

In the picture below I hadn’t blocked my sweater, since I’m using a different sweater as an example, so just pretend it’s blocked.

Measure the length of that piece of yarn with a ruler, making sure not to stretch the yarn to get a false reading (and measure it a little neater than I did—I couldn’t get the tripod to show what I was doing while I held it down with my fingers). Alternately, if you have a flexible ruler, you can use that to measure instead. That’s what I usually do.

That number is 1/2 the perimeter of your sweater armscye. My measurement was 9”, and I have a 36″ chest and narrow shoulders. When I crunched numbers for a 50″ chest and normal shoulders, that number was about 11 1/2″, if that gives you an idea of the range. (Notice that’s not much of a difference, even between 14″ of sizes.)

Note that this measurement is half the perimeter of your armscye, not the entire perimeter. This will be a reoccurring theme as we calculate our numbers, because in the end we’re going to do the math on half the sleeve. It just works out easier that way since all the shaping is mirrored on both the right and left side. So when we’re doing all this, think of a sleeve folded in half.

Measurement L from this step: 1/2 armscye perimeter of your sweater (in inches)

Your measurement L: _______ inches

Prep step 2: Figure out the width of what you bind off on the first row at the armhole

When you knit your sweater, you know that you bind off a certain number of stitches that marks the beginning of the armhole (in Briar Rose, this is 4 sts per side). It gives you a relatively small horizontal bound off edge on the body of your sweater. See between the blue lines below:

You will do the same thing at the start of your sleeve cap, using the same number of stitches per side. This number matches in most knitting patterns because you’ll be sewing those areas together, and it makes a nice fit. In the Briar Rose pattern as written they actually skip this part (and just launch straight from the upper arm into decreasing one stitch each edge of every other row). But I would highly recommend it. It’s not absolutely imperative that the number of bound off stitches be the same, so if you have to fiddle with your numbers a bit and bind off a little more for your sleeve cap, do so. I just wouldn’t recommend binding off less.

So if you bind off 6 stitches at the armhole edge of the sweater, you will bind off 6 sts at the beginning of the first two rows of the sleeve cap. We need to know how wide this is in inches as well, so divide it by your gauge. This will be Measurement M. For example:

6 (sts to bind off) ÷ 6.5 (stitch gauge) = .92”

Don’t worry about the decimal, we’ll smooth that out later.

Measurement M from this step: width of what you bind off on the first row at the armhole (in stitches and inches)

Your Measurement M: _______ sts, _______ inches

Prep step 3: Figure out the width of your sleeve at the upper arm

You will need to know both how wide your sleeve will be at the upper arm (for those of you who resized Briar Rose, this was Measurement K from the resizing post), and how many stitches this works out to be at your gauge. This is as wide as your sleeve is going to get, before you start binding off to start shaping the sleeve cap.

You’ve already done this if you resized your sweater, but if not here’s a refresher. Say you want your sleeve to be 13″ wide at the upper arm.

13” (width at upper arm of sleeve) x 6.5 (stitches per inch) = 84.5, round down to 84 for an even number, and add 2 sts if you’re seaming = 86 sts at upper arm

You need to know how many stitches here because, well, you’ll need to know when you knit it obviously. You’ll also need to know because you’ll decrease away from this number to a smaller number to shape your cap, so you need to know what your starting point is. These numbers make up your Measurement N.

Measurement N from this step: width of your sleeve at the upper arm (in stitches, and inches)

Your measurement N: _______ sts, _______ inches

Prep step 4: Figure out 1/2 the width of your sleeve at the upper arm after bind off

When you calculate this number, you’re not going to include the stitches you bind off at the beginning of the sleeve cap, because we want to know 1/2 the width of the actual number of stitches we have to work with once we start working the sloped sides of the cap.

Take the number of stitches from the previous step and subtract from it the number of stitches you bound off at the armhole over two rows in the sweater body. That is, if you bound off 6 stitches at the beginning of 2 rows, that’s 12 total sts bound off (6 for the left side of the sleeve, 6 for the right).

The number you’re left with is the number of stitches you have left on the needle. This is the number you’ll be decreasing away from to get you to the top of your sleeve cap. Divide this number by 2 (round to a whole number if you get a fraction), then divide by your gauge to know how wide this is in inches.

(Alternately you could have obtained this number by dividing the width in inches of your sleeve at the upper arm by two, then subtracting the width in inches equivalent to the stitches you bind off in those first two rows. Both get you to the same place. Any difference of a small fraction of an inch due doesn’t matter.)

Example:

86 sts (on the needle at the upper arm) – 12 sts (BO at each side of the armhole) = 74 sts

then…

74 sts ÷ 2 = 37

then…

37 ÷ 6.5 (stitches per inch) = 5.69 inches

So that means Measurement O in this case would be 5.69”, or 37 sts.

Measurement O from this step: 1/2 width of your sleeve at the upper arm after bind off (in stitches, and inches)

Your measurement O: _______ sts, _______ inches

Prep step 5: Figure out the width at the top of your sleeve cap

Pleated sleeve cap or normal, fitted sleeve cap? You have to decide now before you do the math in this step. Why? It affects the final number of stitches you bind off at the end of the sleeve cap. The width at the top is a bit subjective. Almost every knitting resources that talks about sleeve caps (admittedly, not all that many of them do in much detail) gives a different range of how wide the top of the cap should be. I’ve seen anywhere from 2” to 6” mentioned. (Beware, 6” is in the super baggy sweater or football linebacker territory!)

In preparation for this post, I surveyed more than a dozen of my 1950s and 1940s patterns knitting patterns that had ‘normal’, fitted sleeves (i.e. not pleated or gathered in anyway, just set in normally) and worked out the math to determine how wide the top of their sleeve caps were. They were between about 2.5 – 3.25”. This is right about what I would expect. You don’t want it too pointy, and you don’t want it too wide.

Now, Briar Rose has a pleated sleeve cap. There is no particular extra shaping involved to make a pleated cap. The top of the cap is simply wider, and then you fold up the edges into little pleats when you sew it up. As written, the sleeve cap for Briar Rose is 4.3” across the top of the cap.

- For a fitted sleeve cap—If you’re on the smaller end of the spectrum or don’t have particularly large arms, you should aim for about 2.5 – 3” at the top of your sleeve cap. If you’re a little bigger, you could add a bit here. Keep in mind though that this is not a measurement that really changes much proportionally. I surveyed some modern patterns with similar fitted sleeve caps and there’s very little difference in the top of a sleeve cap even over 10”+ of sizes. In fact, some have no difference at all among the sizes. I think if you stick within about 2.5” – 3.5” or so you’ll be fine. This is a comfortable range for most people for a fitted sweater.

- For a pleated sleeve cap—The top of the cap is wider because you’ll fold the extra knitted fabric into pleats. 4.3” is the width across the sleeve cap according to the pattern. You could stick with around this, or go a little bit bigger for deeper pleats.

Whichever sleeve cap style you select, decide on how wide the top of the cap will be for your sweater. What would I do? Well I haven’t decided between fitted and pleated yet, in truth. If I knit it fitted, I’ll set the final bind off row to 3”, and if I knit it pleated, I’ll go with the pattern as written, 4.3”.

To determine how many stitches this is, multiply your stitch gauge by the final width you set for the top of the sleeve cap. Round up when necessary (if you get a decimal, or an odd number). This will be Measurement P. For example:

3” (final width at the top of the sleeve cap: normal fitted) x 6.5 (stitch gauge) = 19.5, round up to 20 sts

4.3” (final width at the top of the sleeve cap: pleated) x 6.5 (stitch gauge) = 27.95, round up to 28 sts

Measurement P from this step: width of the top of your sleeve cap (in stitches and inches)

Your Measurement P: _______ sts, _______ inches

Prep step 6: Figure out 1/2 the width at the top of your sleeve cap

This step is slightly different depending on if you’re working a fitted sleeve cap or a pleated sleeve cap.

- Fitted sleeve cap—Take Measurement P from the previous step (the final width of your sleeve cap at the top) and divide it in 2.

- Pleated sleeve cap—Because you have extra ease in the fabric for the pleating, you don’t just want half the width of the final bind off, because that will be too big of a number when we start using these figures. So you need to subtract out that extra ease (because that ease will be pleated). You’ll need to guesstimate a bit here. Decide what you would have used as the width at the top of the sleeve cap if you were not doing pleats. So say for example, that’s 3”, not 4.3”. That remaining 1.3” is how much extra ease you have, i.e. the part you don’t want to include (because you’ll be turning it into a pleat on either side of the cap). So forget about it, and divide the remaining 3” in half. So in this case, the number would be 1.5”.

The result will be Measurement Q.

Measurement Q from this step: 1/2 the width at the top of your sleeve cap (adjusted if using pleats)

Your Measurement Q from this step: _______ inches

Prep Step 7: Figure out the length of the slope of your sleeve cap

Remember how I said that the perimeter around the sleeve cap needs to be the same (or slightly longer) than the perimeter of the armhole (armscye) of the sweater? This is where that comes into play.

You know what the 1/2 armscye perimeter of your sweater is (Measurement L). You know the width over the stitches you bound off at the beginning of the sleeve cap (Measurement M). And you know 1/2 the width at the top of the sleeve cap (Measurement Q).

What remains is Measurement R, the length of the slope part of your sleeve cap that I showed earlier.

So subtract Measurement M (width of what you bind off on the first row at the armhole) and Measurement Q (1/2 the width at the top of your sleeve cap) from Measurement L (1/2 armscye perimeter of your sweater).

Measurement L – Measurement M – Measurement Q = Measurement R

Measurement R from this step: length of the slope of your sleeve cap (in inches)

Your Measurement R from this step: _______ inches

Prep steps are now done!

What we’re going to do in Part 2 is figure out the height of our sleeve cap, i.e. how tall it is. Part 2a is the method using pieces of paper and a ruler to lay out your sleeve cap, the actual size it will be. There are other ways of coming up with the same math, but I’ve found this method a) works well and b) doesn’t involve making you guys all calculate the Pythagorean Theorem when you don’t want to and c) is kind of nice for those people who like to have a real visual of what they’re going to be doing. But for those of you who want the hardcore math (it’s not that hardcore, seriously!), skip ahead to Part 2b.

Part 2a: Figure out the height of your sleeve cap: the paper and ruler method

In this method you’ll need a calculator, a ruler, a piece of paper to cut up, a pen or pencil and a straight edge like a book or another piece of paper.

We’re going to build half of our sleeve cap with pieces of paper. Only half because we’ll then double it up to get the whole size.

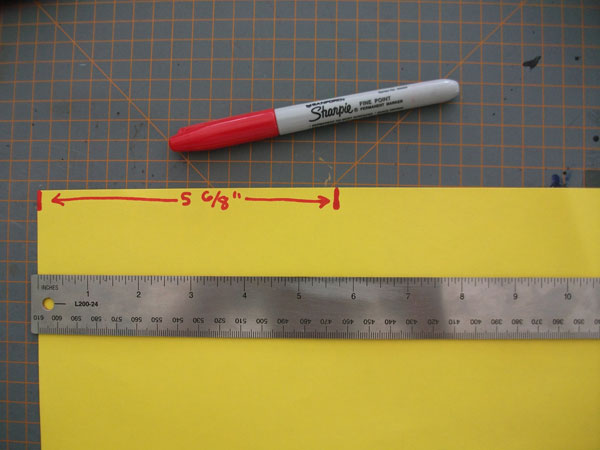

1) Take Measurement O in inches (1/2 width of your sleeve at the upper arm after bind off), which is 5.69” for me. Remember, this represents the stitches you have left on the needle after the bind off at the underarm to get you to the desired width at the top of your sleeve cap.

We’re going to draw this on the edge of a piece of paper. But wait… try to find 5.69” on a ruler.

Yeah, not so much.

This would be a good time to mention you’re going to need to round to a number that will actually show up on a ruler. You can round to 1/16th of an inch, but 1/8th of an inch is perfectly acceptable and easier to round to.

If you’re not sure how to do that, here’s a cheat sheet.

1/8 = .125

2/8 = .25

3/8 = .375

4/8 = .50

5/8 = .625

6/8 = .75

7/8 = .875

8/8 = 1.00

In my example, I ended up with 5.69”, so I would just round that .69 part up to .75. Why round up? Because you never want your sleeve cap to be smaller than your armhole. Therefore I round up. You can always ease a little extra in, but you don’t ever want your sleeve cap too tight across your shoulder (I know I said that before and I’ll probably say it again). So that works out to 5 6/8. That’s easy to find on a ruler.

Make sense?

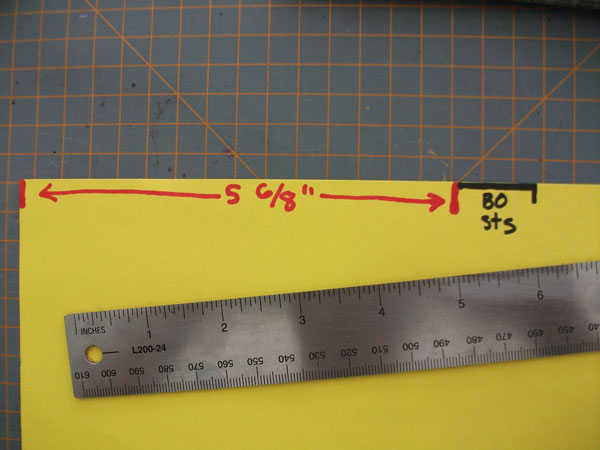

2) On the edge of a sheet of paper, mark a line the same length as the number of inches you just came up with (i.e. 5 6/8”).

I actually like to add in the width of the bound of stitches for a visual on the right of this line. You don’t have to, but I find it somewhat helpful to “see” the sleeve cap.

Put the left edge of your line up against a straight edge, like the side of a magazine, a ruler, another piece of paper, etc. (I happened to use a vintage knitting booklet.) This edge represents the halfway point of your sleeve. Pretend the other half of your sleeve is under the straight edge.

The right side of your line marks the edge where you’ll be decreasing, i.e. where your slope will form (if you also draw on the bind off stitches, that may be more obvious). I like to tape down the piece of paper so it doesn’t move around.

3) Take Measurement Q (1/2 the width at the top of your sleeve cap, adjusted if using pleats). If I just do a plain fitted cap, mine will be 1.5” so I’ll go with that. If you have to round up to the nearest 1/8th, do so now. Draw the length on a piece of paper, and cut it out:

4) Place the left edge of this piece of paper about 5 or 6 inches above the other piece of paper. This really doesn’t need to be exact since you’ll be moving it around shortly. Just make sure it’s lined up so that the left edge of both your pieces of paper are lined up against the straight edge. That’s the important part.

Can you start to see the shape of an invisible sleeve cap taking form?

5) Take Measurement R (length of the slope of your sleeve cap). Mine is 6.58”. If you have to round up to the nearest 1/8th, do so now. Draw it on a piece of paper, cutting it out as so:

This would be a good time to make a suggestion: double check your measurements. Why? Because I discovered this piece of paper was really one inch too short. Don’t make that mistake!

6) Now connect the dots. Line up one edge of this piece of paper with the right-hand edge of the line on your bottom sheet of paper, the one representing the half width of your sleeve after the BO rows. Line up the other edge with the right-hand edge of your top piece of paper, the one representing the half width of the top of your sleeve cap (or adjusted half width if you’re doing pleats). Play with the pieces a bit until everything lines up at the corners. Again I’d suggest taping them in place so they don’t move around.

7) Got ‘em lined up? Great! Now measure the height between the top and bottom pieces of paper. This is how tall your sleeve cap needs to be. This is Measurement S. I got 5 3/16”, or converted to decimals since that’s what we use when we’re talking about gauge and stitches, that’s 5.19”.

You also need to know how many rows this represents, so multiply Measurement S by your row gauge (not stitch gauge!). Round to an even number of rows as it will be easier to work with (since you need to do the same thing on both sides of your sleeve).

5.19” (Measurement S, height of sleeve cap) x 10 (rows per inch) = 51.9 rows, round up to 52 rows

Note: If you arrive at an odd number for Measurement S, round up to the next even number.

Using the paper and ruler method, I determined that my sleeve cap needs to be 5.19” tall, over 52 rows.

We’re done with this part! You can skip 2b, which explains how to get the same number but with the Pythagorean Theorem, unless you’d like to learn that method as well.

Part 2b: Figure out the height of your sleeve cap: the math method

In this method, we use the same numbers measurements we took earlier, but we let the calculator do our work instead of pieces of paper. We’re still solving for Measurement S (height of our sleeve cap).

Actually, we’ll need to gather one more number to get started. Subtract Measurement Q from Measurement O.

Measurement O (1/2 width of your sleeve at the upper arm after bind off in inches) – Measurement Q (1/2 the width at the top of your sleeve cap in inches–adjusted if using pleats) = Measurement T

Measurement T is the width decreased by your sleeve cap on one side. For my calculations, Measurement T is 4.19”.

At this point I really need to show you a visual of what we’re going to do in 2b. Recall our sleeve cap from earlier. I’ve shaded out half of it, since we’re still only working with half the cap as you know. So ignore the left half.

We’re solving for that big blue question mark, which is the height of your sleeve cap (the same thing that our paper and ruler method gave us in step 2a), Measurement S.

Measurements R and T and that question mark form a triangle. Measurement R is the hypotenuse of that triangle. Measurement T is the base of the triangle. We need to solve for the other side.

The Pythagorean Theorem allows for us to solve for side a, which is the height of our sleeve cap. You need to find out the square root of c2 – b2. Here’s the same sleeve cap, but broken down into the those parts of a triangle: sides a, b and c.

You could do this on a calculator, but it’s nicer to just do it online, don’t you think? This Trigonometry Calculator will do the work for you.

The triangle is facing a different direction in their example, but it doesn’t matter. We know side c (our Measurement R) and we know side b (our Measurement T). Plug those into the calculator and hit “calculate”. That will give you Measurement S, the height of your sleeve cap. Here’s what mine looked like:

My Measurement S is 5.07”, up there in the highlighted yellow box. I also want to know how many rows that is, so I multiply it by my row gauge. You want to round up to the nearest even number of rows.

5.07” (Measurement S, height of sleeve cap) x 10 (rows per inch) = 50.07 rows, round up to 52 rows

Note: If you arrive at an odd number for Measurement S, round up to the next even number.

Using the math method, I determined my sleeve cap should be 5.07” tall over 52 rows.

And that’s it for Part 2! Whether you choose the paper and ruler method or the math method, you need to find Measurement S, the height of your sleeve cap.

One last thing… if you were playing along at home, did you notice my numbers were slightly different depending on which method I used?

paper and ruler method: 5.19” tall, over 52 rows

math method: 5.07” over 52 rows

This difference is negligible. It came out slightly larger using the paper and ruler method. This is because using the paper and ruler method, we rounded up to be able to find numbers more easily on a ruler, so the result was slightly bigger. In the end, the difference would probably not matter in the slightest. However if you are concerned, always round up a little. You can ease in a little extra fabric but you’ll forever be annoyed if your sleeve cap is too tight across your shoulder. I would rather err on the side of too much fabric than too little, so I will be adding in a few extra rows when I actually plot my cap.

Part 3: Figure out your last few measurements before plotting your decreases

However you arrived at Measurement S, using either Part 2a or Part 2b, it doesn’t matter.

You know how big your sleeve is at the widest part of your arm (Measurement N). You know how many stitches you’re going to bind off in the first 2 rows of the sleeve cap (Measurement M). You know how wide the top of your sleeve cap will be (Measurement P). And you now know how tall your sleeve cap will be and how many rows it will take you to get there (Measurement S).

Now you need to figure out how to decrease after those first two bind off rows at the beginning of the sleeve cap, to get you up to the end of the cap.

Most sleeve caps aren’t shaped as basic as the drawings I’ve been using. Some people might call that a “simple”, “basic” or “traditional” sleeve cap. You bind off a certain number of stitches at the underarm, then decrease one stitch on each edge every right side row (AKA every other row) until you get to the desired cap height or the desired width at the top of the cap. The problem with this method is that it may not actually end up being the same perimeter (or slightly larger) as the armhole of your sweater. Now, the math might work out perfectly for you to do this over the number of rows you need your sleeve cap to be. But it might not.

More frequently, a sleeve cap is shaped like a gentle bell curve. Something a little closer to this:

To achieve a cap that’s closer to this kind of shape, patterns will often have you work your pairs of decreases (remember, one on each edge) in three areas:

- faster increases at the bottom (usually decr 1 st each end of every other row)

- slower increases in the middle (more like decr 1 st each end of every 4th or 6th row)

- faster increases again at the top

Kind of like this (though admittedly this isn’t really to scale):

Sometimes to make the top even more gently curved at the very end (which can be a little easier to sew into an armhole), patterns will have you bind off 2 stitches every row for 4 or 6 rows just before that last final bind off row. It can make it easier to smoothly sew in the top portion of the sleeve cap into your armhole. It really just depends.

With all these slight variations, I’m sure you’re starting to realize you can pretty much do this any number of ways and have it work for you! I really can’t tell you the one right way to do it, since there is no one right way to do it. I’m not sure whether or not that’s encouraging or discouraging… I prefer to think of it as encouraging since it gives you more freedom!

We have one more number to gather and then we can start figuring out how to work our decreases. We need to know how many stitches we have on the needle after we work our first two bind off rows at the bottom of the sleeve cap. That’s just Measurement O in stitches multiplied by 2. In my case, that equals 74 sts. We’ll call this Measurement U. My Measurement U is 74 sts.

The main information you’ll need to work with is as follows:

- Measurement U: How many stitches do you have on the needle after your initial 2 BO rows at the bottom of the sleeve cap? (for me: 74 sts)

- Measurement S: How many rows do you have to fit in all your paired decreases? (for me: 52 rows)

- Measurement P: How many stitches do you have on the needle after your last decrease row is worked, i.e. how many stitches will you BO at the very end? (for me: 20 sts)

But remember how I said that the sleeve cap can be up to about 1″ or so larger than the perimeter of your armscye? I think I’ll add a few more rows to my Measurement S just as a safety net, to ensure I don’t end up with a sleeve cap that’s pulling too tight across my shoulder. So I’m going to bump up my Measurement S to 60 rows. (Incidentally, I also did this when I discovered with my first round of calculations I had 54 rows to decrease 54 sts, meaning with my math I’d perfectly be able to decrease 1 st at each end of every right side row and arrive at my desired width at the top of my sleeve cap, and that doesn’t make it a very helpful example for you!)

What you have to do is figure out how many decreases you’ll need to make. For me, that number is 54 stitches. How do I know? I start with 74 sts after the initial BO of my sleeve cap (Measurement U) and end my cap with 20 sts (Measurement P). 74 – 20 = 54.

So I need to decrease a total of 54 stitches. But I want to know how many decreases this works out to per side (since we decrease at the same rate on each edge of the sleeve cap). So 54 ÷ 2 = 26. That means I have a total of 26 sts I need to decrease per side. We’ll call this Measurement V (and hoorah! this is the last damn measurement).

Now I need to figure out how to plot out 26 decreases (Measurement V) on the side of my sleeve cap.

Part 4: Figure out how to plot your sleeve cap decreases

You know how many decreases per side of your sleeve cap. In my case that’s 26. There are a number of ways you could do this (are you surprised?). You can print out graph paper and using one square to represent one stitch, draw out your cap and figure out your decreases, indenting a square for each stitch decreased.

However, I particularly like using the taper formula on p. 53 of an out of print book, Knitter’s Guide to Sweater Design, by Carmen Michelson and Mary-Ann Davis, published by Interweave Press. I actually contacted Interweave because I wasn’t really sure I could discuss the formula on my blog without violating copyright. They were kind enough to reply (and in a very timely fashion, I might add!) and gave me permission to do so as long as I cited the book and page number. I was more than happy to comply, because I love the book and I love this formula. So thank you, Interweave, I really appreciate it!

The same concept is used in another of my knitting resource books, however I like their taper formula because using it reminds me of doing Choose Your Own Adventure books in grade school, or those silly games that start off like “Take the year you were born, add 100 to it, subtract blah blah…”

All you need to know for this part is Measurement S, the height of your sleeve cap in rows (in my case I decided that would be 60 rows) and Measurement V, the number of stitches you want to decrease in your cap per side (in my case that’s 26 sts).

You basically follow a series of steps, which will result in finding out how many faster and slower decreases you can use in your sleeve cap using the exact number of rows you’ll need for the height of your cap.

Once you know that part, you can easily decide how you’d like to plot them out on your cap. Work all the faster decreases, then the slower ones. Work half the faster decreases, then the slower ones, then the remaining faster ones (the way that forms the most gentle bell shape). It’s up to you! But you’ll know exactly which decreases to work and how many of them.

Let’s start.

Step 1) Work Measurement S ÷ Measurement V.

Example: 60 ÷ 26 = 2.3

- If the result doesn’t contain a decimal (i.e. is a whole number) and is an even number (i.e. 2, 4, 6), you’re done! Work 1 decrease at each end of every right-side row until you get to how many stitches you are supposed to bind off in the last row of your cap (Measurement P).

- If the result is 1 and a fraction (i.e. 1.4, 1.6, 1.7), make note of the number and proceed to Step 6. (**I think this is less likely to happen in a sleeve cap, btw.)

- If the result is any even number and a fraction (i.e. 2.3, 4.1, 4.6), make note of the number and proceed to Step 2.

- If the result is an odd number that isn’t 1 or an odd number and a fraction (i.e. 3, 3.7, 5.2), make note of the number and proceed to Step 3.

Step 2) Write down the even number and the next higher even number. Then proceed to Step 4.

Example: If your result was 2.6, write down 2 and 4. If your result was 4.3, write down 4 and 6.

What this means: you will work decreases every (lower even number) and (higher even number) rows, i.e. every 2nd rows and every 4th rows.

Step 3) Write down the next lower even number and the next higher even number. Then proceed to Step 4.

Example: If your result was 3.2, write down 2 and 4. If your result was 5.8, write down 4 and 6.

What this means: you will work decreases every (lower even number) and (higher even number) rows, i.e. every 2nd rows and every 4th rows.

Step 4) Work the following: [ (Measurement V x higher even number from Step 2 or 3) – Measurement S ] ÷ 2.

Example: ( [26 x 4] – 60 ) ÷ 2 = 25. Want that written out? 26 multiplied by 4 is 104. Subtract 60 from 104 = 44. Divide 44 by 2 = 22.

What this means: You will work decreases every (lower even number) rows this many times, i.e. every 2nd row 22 times.

Step 5) Work Measurement V – Step 4.

Example: 26 – 25 = 1.

What this means: You will work decreases every (higher even number) rows this many times, i.e. every 4th row 1 time.

Total from Steps 1 through 5 means you know to work 1 decrease on each end of every 2nd row 22 times and every 4th row 1 time. (How you decide to split them up is up to you.) DONE!

Step 6) Work Measurement S ÷ 2. Then proceed to Step 7.

Example: 60 ÷ 2 = 30. (**Note this example doesn’t use my real math since I had an even number originally, so I’m just putting in some numbers here as an example. For Steps 6-8 pretend Measurement V is 34 and Measurement S is 60.)

What this means: You will work this many decrease rows, i.e. 30 decrease rows.

Step 7) Work Measurement V – Step 6. Then proceed to Step 8.

Example: 34 -30 = 4.

What this means: Because in this scenario you end up having more increases that can be done in every other row in the number of rows you need for your sleeve cap, you’ll have to do some rows that actually BO 2 sts (and since you can’t BO sts on either side of a row unlike the decrease rows, you will do it at the beginning of each row). So in this case, you will have 4 rows where you will BO 2 sts at the beginning of each row (i.e. decreasing two stitches per row, i.e. decreasing a total of 4 sts per side).

Step 8) Work Step 6 – Step 7.

Example: 30 – 4 = 26.

What this means: This is the number of decreases you’ll work every 2 rows (i.e. every other row, i.e. every right side row).

Total from Steps 1 and 6 through 8 means you know to BO 2 sts at the beginning of 4 rows and 1 decrease each end of every 2nd row 26 times. (How you decide to split them up is up to you.) DONE!

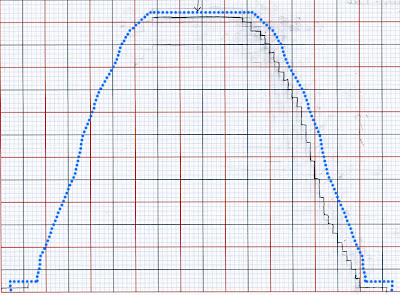

Okay! We now know what pairs of decreases we need to work. Admittedly, my example came out kind of silly. I’m supposed to decrease on each end of every 2nd row 22 times and every 4th row 1 measly time. That’s 22 fast increases and only 1 slow increase. In actuality, I’d kind of like to have my cap more gentle at the top. Remember when I said earlier that some patterns have you bind off 2 sts at the beginning of 4 or 6 rows just before the final long bind off on the sleeve cap? You can always decide to do that, and THEN work the taper formula. Just work the formula taking out the number of decreases that it would include and the number of rows. I actually did just this, and I’ll show you what it looked like when I charted it on graph paper.

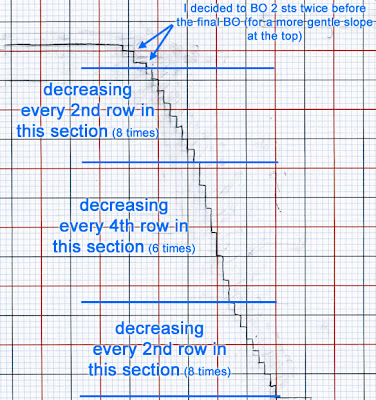

Each box represents one stitch, and this shows half my sleeve cap (since again, we know we just repeat everything on the other side). This is my actual working copy, see all the notes and erase marks? This isn’t pretty, people, but this is the real deal!

(click to enlarge)

(click to enlarge)

Can you “see” the sleeve cap?

(click to enlarge)

(click to enlarge)

I had 60 rows over which to work my 26 sets of decreases, but I decided to throw in two sets of BO 2 rows at the top of the cap, which uses up 4 rows (since you do it on each side). So I did my math using 54 rows and 22 sets of decreases. And the above is what I got. 16 sets of decreasing every 2nd row and 6 sets of decreasing every 4th row. I decided to split up the faster decreases and put them at the bottom and the top. You can see it makes a pretty nice curve.

(click to enlarge)

(click to enlarge)

You certainly don’t have to plot it out on graph paper. In fact, I find it a little annoying, but I wanted to give you guys a good visual.

Part 5: Putting it all together

Now that you know how to work your sleeve cap decreases, you can put that in your pattern and call it a day. Phew!!

My Pattern:

SLEEVES.

Using smaller needles, cast on 80 sts.

Work in rib of k1, p1 for 2.25″.

Using larger needles, work in st. st, increasing 1 st each end of every 4th row until increased to 86 sts.

When work measures 6″, shape sleeve cap as follows:I’m just going to plug in my numbers from the steps in this post:

Shape sleeve cap as follows: BO 6 sts at the beginning of next 2 rows.

Decr 1 st at each end of every 2nd row 8 times.

Decr 1 sts at each end of every 4th row 6 times.

Decr 1 st at each end of every 2nd row 8 times.

BO 2 sts at the beginning of the next 4 rows.

BO remaining 20 sts.

And… dare I say it? We’re DONE! Can you believe it took that long of a post to get a few little lines of information? lol

Final thoughts

Figuring out your sleeve cap does take a bit of work, I admit. This post took me approximately forever to compile, and I hope I was able to do the topic justice in a somewhat coherent way. Read through this post more than once so you start to understand the concept. We figure out how tall our sleeve cap needs to be, based on our own sweater, to make sure it will fit into the sweater. Then we figure out how to shape it. That’s all we’re doing, it just takes awhile to get there.

I encourage you to seek out other resources on this topic, too. By no means do I claim to have the only way to do it. This is just the way I have found the easiest and most accurate way for me to do it. As I continue to read about the topic, I’m sure I will tweak my methods over time. You never stop learning!

At the end of the day it’s up to you to decide how you want to shape your sleeve caps. Please feel free to post in the Flickr group with any questions! As you know, I am always more than happy to help out.

If I haven’t scared you off, I’ll leave you with some resources for today…

Online resources for this post:

- Ravellings on the knitted sleeve parts 1, 2, 3—Jenna Wilson’s series for Knitty is nothing short of extraordinary. There is so much in-depth information here on sleeves and sleeve caps. Well worth diving in for those who really want to take control of their knitting.

- The Magic Formula Calculator—This is a nice calculator for increases and decreases. You can use this for sweater bodies, sleeves and sleeve caps. Just keep in mind it will place the decreases/increases on right and wrong side rows, so be aware that you’ll either need to do some additional math to get them all on the right side, or you’ll be knitting some increases/decreases on purl rows if you’re knitting flat. If my post intimidates you and you don’t mind working decreases on RS/WS rows, plug your numbers into this calculator.

- A Knitting Calculator for Set-in Sleeves—This can take a little bit of work to make it meaningful for you, but it’s well worth checking it out. Though it won’t help in the actual plotting of your cap decreases.

- Graph Paper—You can have it create graph paper in multiple sizes to print. This is what I used in my examples in this post.

- The list of Measurements gathered for this post

I only stay 5 years in the university, not sure it’s enought to realize this work ha ha ha !!!

You ‘re so courageous to do great thing and explain to people like me 😉

Wow wow wow – This post is amazing. I’m not doing the knit-along, but I’m following with interest and would love to be able to knit this someday. Thanks for being so thorough!

This makes me so excited for classes to end so I can start on the Briar Rose!! I am going to be doing the KAL but I need to wait until school is over. I hope to have it done by the time of the show off date!!! 🙂

You are a soooper genius.

!

My goodness! What an amazing post!!!!

All I can say is that I am thankful I am the same size as the directions and don’t need to fiddle around. This is sooooooooo beyond me. You my dear are amazing. My eyes started going around in circles like a cartoon character. Maybe I will have to read this at night with a bottle of wine. I’m sure it will make more sense to me with alcohol!!!!

Thanks so much for your hard work! I just got my bind off row to start shaping the armhole. I couldn’t have gotten this far without your help. I think I may have to have my son help me with the math for the sleeve. Thanks!

Thanks guys! ♥

It really helps to hear that I haven’t completely lost my mind. 😉

Wow! Ok, I really pretty much skimmed that with wide eyed wonder… or fear… I’m still only on maybe the first row or two of my increases!

@Moxie Tonic Don’t be scared! When you get to that point and you have your numbers, it will make much more sense. 🙂

Having just reknit badly drafted sleeves twice, I must say this little page is a godsend. Thanks so much. Quick note – I think there is a typo in Step 4’s Example: ( [26 x 4] – 60 ) ÷ 2 = 25. Should be 22, which you correct later in step 4, but the error is advanced to Step 5. Not a big deal and again, thank you so much!

Wow ! A great work ! Congratulations … I have seen it weared. So nice.

Thank you, thank you for this great post. I’ve been knitting a cardigan for myself using a free pattern I found online and the sleeve decreases just didn’t work for me. I had misgivings as soon as I began the decreases past the armhole (the pattern had me casting/binding off 2 sts each end of every row for 16 rows) and once completed I knew that it wasn’t going to fit. The cap perimeter was at least 6″ too short! I found your post this morning after mulling over this problem all night, and now that I’ve done the maths, I can’t wait to get my knitting out again and see if I can make those sleeve caps work! So thank you so much.

I’m so happy to hear that, I hope it works out for you! It can be a bit fiddly to work out, but it gives you so much control over the result. 🙂

Thank you *so* much for taking the time and effort to write this post! I’m knitting a cardigan and because my row gauge is off I realized I needed to re-design the sleeve cap. I found the whole concept totally terrifying, but this post makes it seem completely doable (even if it does take some time). Thank you thank you thank you!